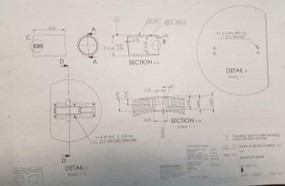

CUSTOM MACHINING OF A LARGE ALUMINUM HUB USING CNC TURNING AND MILLING MACHINES FROM CUSTOMER’S SOLID MODEL DRAWING

A local Space Component Manufacturer contracted Denver Machine Shop to build a very special hub to extreme high tolerance for use with a part that will one day be used on a communication satellite. Using , 6061 Aluminum the unit was turned one of our state of the art larger CNC Lathes and then it was milled on one of our high precision CNC Mills. A Tight tolerance of ±0.0005″ was held throughout. After polishing the part to a 32 RMS finish, the unit was then anodized for hardness. Turnaround time for this project was rushed to 3 weeks.

The finished dimensions were 14 inches in diameter by 28 inches in length with a wall thickness of 1-1/2 inches. Total weight was 75 lbs. Denver Machine is a reliable source for high quality custom OEM parts, rebuilds, and custom manufacturing. For more about this satellite hub project or our other value added services please see the table below or contact us directly.

HIGHLIGHTS OF THIS CUSTOM MACHINING PROJECT

| Product Description | Used for adjusting a plug mill in a steel mill application | ||

| Capabilities Applied/Processes |

|

||

| Equipment Used to Manufacture Part | CNC Lathe 23” x 10′ between Centers, Vertical CNC Mill | ||

| Overall Part Dimensions | Product Weight: 120 lbs. Product Length: 24’’ , Diameter: 14″ |

||

| Tightest Tolerances | ± 0.0005″ | ||

| Material Used | 6061 Aluminum | ||

| Material Finish | 32 RMS | ||

| Additional Facts | Extreme tight tolerance required for Space Manufacturing | ||

| In process testing/inspection performed | Functionality Testing, CMM dimensional testing | ||

| Industry for Use | Space | ||

| Volume | 1 ea | ||

| Delivery/Turnaround Time | 3 Weeks | ||

| Delivery Location | Colorado | ||

| Standards Met | Customer Specifications, 3D CAD Solid Drawing | ||

| Product Name | Spoke Hub |